7 Heavy Machinery Operators’ Deadly Sins – Easily Increase Productivity & Safety

Ignoring Pre-Operation Inspections, Failure to use proper safety gear, overloading the machines, poor communication with the crews are some of the deadly sins trainees, heavy machine operators encounter in Uganda, Democratic Republic of Congo and South Sudan among other countries.

There is something that could essentially modify the way you work, I have personally witnessed the mistakes and faults that many heavy machinery operators endure, and I’m sure you have as well.

Whether you work in Uganda, South Sudan or Democratic Republic of Congo, these “7 Deadly Sins” may be harming your productivity and, more importantly, safety. I know you want to do the job well, and you may already have some relevant experience.

We are all aware that even the most experienced operators in any parts of the country can develop poor habits. So, let’s take a look at these mistakes and how avoiding them can easily improve your performance and safety as you continue to discover more below;

1. Ignoring Pre-Operation Inspections

You are ready to get to work. The machine is powered on, and the clock is ticking, but you missed the pre-operational inspection to save time, right?

That is where it all begins: the first terrible sin. It’s tempting to feel you know the machine well enough and that everything will be fine. But, believe me, failing these tests can lead to major problems down the road.

Consequences of Ignoring Pre-Operation Inspections:

Skipping the inspection may result in equipment failure during the day, causing delays in your work, costly repairs, and even dangerous situations. I have seen this happen before: an operator fails to check the fluid levels, causing the engine to overheat halfway through the shift.

The machine is out of function for several hours, and the project’s timeline is pushed back.

Way Forward:

You have to review the pre-operation checklist each time. Inspect fluid levels, tire pressure, and other essential parts. It only takes a few minutes, but it can save you hours of downtime and potentially dangerous circumstances.

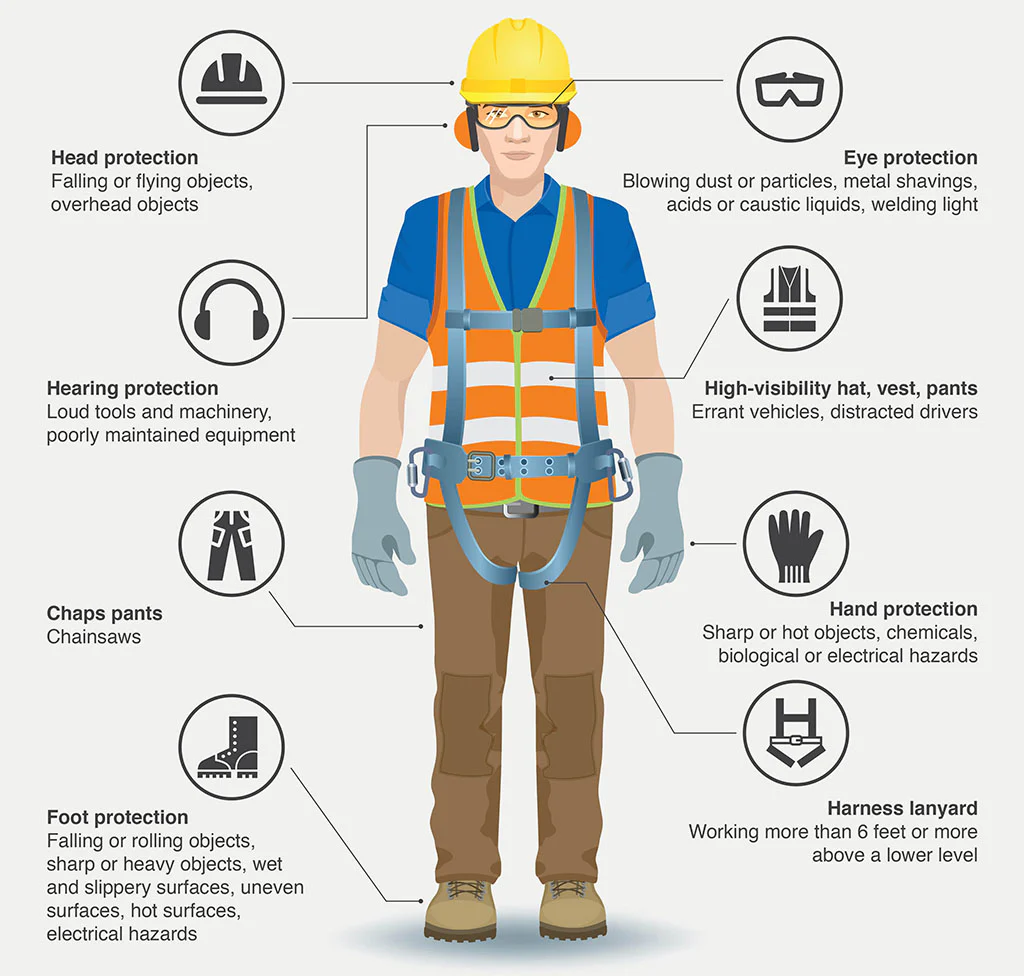

2. Failure to Use Proper Safety Gear.

You know what you are supposed to wear? A helmet, gloves, and steel toed boots. Let me guess: you occasionally leave them in the vehicle, especially on “easy” days, right? Perhaps you think it is unneeded. A big mistake.

Consequences of failure to Use Proper Safety Gear:

Operating heavy machinery without suitable equipment is similar to playing a game without protection. A single slip or unexpected incident can result in a major injury. It’s easy to believe that it will not happen to you, yet it only takes a second for anything to go wrong.

What you can do:

Make it a habit to wear all required safety equipment, even for the simplest jobs. It’s a simple step toward protecting yourself against possibly life changing injury. And, let’s be honest, the discomfort of wearing gear pales in comparison to the despair of a major injury.

3. Overloading the Machine

Overloading the machinery is a further sin that I have witnessed several times. I understand how tempting it is to complete more work at once. However, it is risky and ineffective to drive the equipment over its breaking point.

Consequences of overloading the machines:

Overloading the machine puts unnecessary strain on the engine, hydraulic systems, and tires. It also increases the risk of tipping or losing control. Not to mention, the wear and tear on the equipment will shorten its lifespan and lead to costly repairs.

What You Can Do:

You have to understand and respect your machine’s limits. Even though it can seem like a slight setback at the time, stick to the suggested load capacity. Keeping the equipment in good working order and avoiding mishaps will eventually save you time and money.

4. Poor communication with the crew

I take it that you are working with a crew? Accidents can often result from poor communication. Poor communication may be fatal on any job site, whether it’s failing to confirm tasks or appropriately signal the ground staff.

Consequences of poor communication with the crew:

A lack of clear communication can result in collisions, accidents, or even injuries. For example, I have seen a situation where an operator didn’t get the right signal, and ended up digging in the wrong spot leading to costly delays and a frustrated crew.

Way forward:

Have open lines of communication with your workers. Make use of hand signals, radios, or any other technique that guarantees everyone is in agreement. Your day will run more smoothly and safely as a result.

5. Ignoring Continual Upkeep

When you have a busy timetable, maintenance may seem like a burden, but ignoring it is one of the deadliest sins you can make.

Consequences of ignoring continual upkeep:

Skipping regular maintenance on your machine will lead to unexpected breakdowns, increased repair costs, and downtime. worse, an unmaintained machine is most likely to malfunction during operation putting both you and the job at risk.

What You Can Do:

You stick to the manufactures’ maintenance schedule, even if it means spending an extra hour on upkeep. This small investment in time will ensure your equipment last longer and perform better.

6. Poor site awareness.

Heavy machinery operators are often so focused on their own tasks that they forget to pay attention to their surroundings. This is a deadly sin that could have serious consequences for both you and your team.

Consequences of poor site awareness:

Lack of site awareness can lead to accidents like hitting of other equipment, worker, or even damaging structures. It’s easy to get tunnel vision when you are operating the machine, but it’s essential to keep your head on controls.

What You Can Do:

As an operator make a mindful effort to be aware of the site, your surroundings, and the people working around you. This means keeping your eyes on the area around you and coordinating with your team.

7. Rushing through tasks.

We have all been trying to finish the job faster to meet deadlines. But rushing through tasks is a deadly sin that often leads to mistakes and accidents.

Consequences of rushing through tasks:

Rushing leads to untidy work, increased stress, and a higher likelihood of mistakes. Whether you miss a critical step in the process or push the machine too hard, rushing can result in accidents and damaged equipment.

What You Can Do:

Take your time to do the job right. Plan ahead, stay focused, and pace yourself. Quality work always wins out over quick work.

In a nutshell, I challenge you to pick one of these sins and focus on correcting it today. Is it better communication with your team? Or maybe you are going to start doing those pre operation checks more carefully?

Whatever it is, take react now, your safety and success depends on it. At Friendly heavy equipment and machinery training School we are keen on the deadly sins and for more tips join us now to help you explore what you can’t imagine.